Iron Casting,Ductile cast iron,High chromium cast iron

Five methods for distinguishing ductile iron Casting parts from gray cast iron parts

2025-03-26

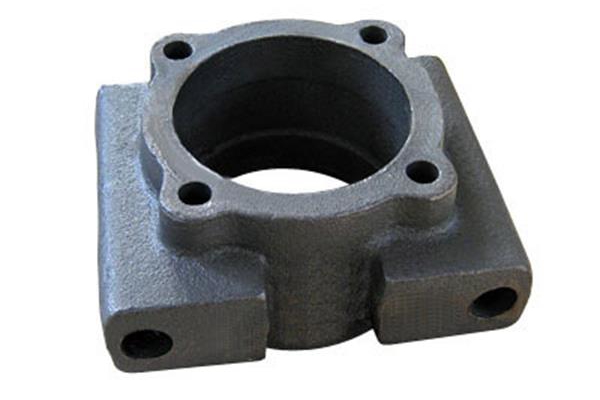

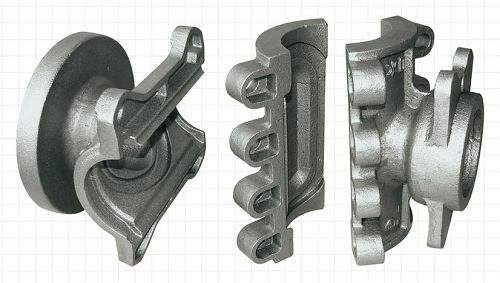

Castings made of Ductile Iron Casting are called ductile iron Casting parts, and are often referred to as "ductile castings". Ductile iron Casting is obtained by spheroidizing and inoculating spheroidal graphite, which effectively improves the mechanical properties of cast iron, and improves plasticity and toughness, thereby obtaining a higher strength than carbon steel. Due to its good strength, toughness, etc., it is widely used.

Five methods for distinguishing ductile iron Casting parts from gray cast iron parts

Because the comprehensive properties of ductile iron Casting are close to those of steel, it has developed into a widely used cast iron material second only to gray cast iron. Ductile iron Casting is an alloy with a wide solidification temperature range and a long solidification time, which is about twice as long as gray cast iron. However, some people tend to confuse ductile iron Castingand gray cast iron in daily life. The following is a simple analysis of the identification methods of ductile iron Casting parts and gray cast iron parts from the aspects of appearance and parameter detection.

1. From the appearance of the knock fracture (not the machined surface), the grains of ductile iron Casting parts are fine and black-gray; the grains of gray cast iron parts are relatively coarse, gray-white, and the crystal surface has a metallic luster.

2. From the processing surface, the processing surface of ductile iron Casting parts is brighter than that of gray cast iron, and the structure is finer than that of gray cast iron parts.

3. Judging by the knocking sound, ductile iron Casting parts have a crisp sound and a long echo, and the knocking sound is similar to carbon steel; gray cast iron parts have no echo and the sound is muffled.

4. From the spark of the grinding wheel, the spark beam streamlines of gray cast iron parts are thin and short, orange-red or dark red, and there are feather-like tail flowers at the tail.

Conclusion

Ductile iron Casting is often used to produce parts with complex forces and high requirements for strength, toughness, wear resistance, etc., such as crankshafts and camshafts of automobiles, tractors, internal combustion engines, etc., as well as medium-pressure valves of general machinery. Nowadays, ductile iron has rapidly developed into a widely used cast iron material second only to gray cast iron.

Ductile iron Casting is an alloy with a wide solidification temperature range and a long solidification time, about twice as long as gray cast iron. The eutectic transformation requires a larger temperature range to complete. The eutectic expansion pressure of ductile iron Casting is about 5 times that of gray iron. An effective measure to reduce and prevent shrinkage cavities and shrinkage of ductile iron Casting is to use high stiffness (hardness) sand molds.

What causes shrinkage and porosity in ductile iron castings

What causes shrinkage and porosity in ductile iron castings

.jpg) Precautions for the production of ductile iron castings

Precautions for the production of ductile iron castings

Ductile iron pieces using national standard iron

Ductile iron pieces using national standard iron

Fluidity and casting process of nodular cast iron

Fluidity and casting process of nodular cast iron

.jpg) Ductile Iron Casting QT600-3(13)

Ductile Iron Casting QT600-3(13)

.jpg) Ductile Iron Casting QT600-3(11)

Ductile Iron Casting QT600-3(11)

.jpg) Ductile Iron Casting QT600-3(12)

Ductile Iron Casting QT600-3(12)

.jpg) Ductile Iron Casting QT600-3(10)

Ductile Iron Casting QT600-3(10)

.jpg) Ductile Iron Casting QT600-3(8)

Ductile Iron Casting QT600-3(8)

.jpg) Ductile Iron Casting QT600-3(7)

Ductile Iron Casting QT600-3(7)