Iron Casting,Ductile cast iron,High chromium cast iron

What causes shrinkage and porosity in ductile iron castings

04-11

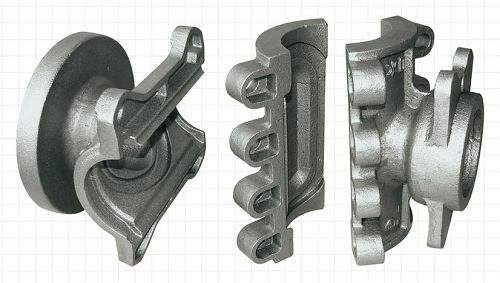

Ductile iron castings are spherical graphite obtained through spheroidization and inoculation. Due to its excellent performance, ductile iron can sometimes replace cast steel and forged steel in use and is widely used in the machinery manufacturing industry.

Ductile iron castings have medium-high strength, medium toughness and plasticity, high comprehensive properties, good wear resistance and vibration damping properties, and good casting process performance. Their properties can be changed through various heat treatments.

Factors causing shrinkage and porosity in ductile iron castings

(1) Carbon equivalent: Increasing the carbon content increases graphitization expansion and reduces shrinkage and porosity. In addition, increasing the carbon equivalent can also improve the fluidity of ductile iron, which is beneficial to feeding. When increasing the carbon equivalent, other defects such as graphite floating in the casting should not be caused.

(2) Phosphorus: The phosphorus content in the molten iron is high, which expands the solidification range. At the same time, the low-melting-point phosphorus eutectic cannot be replenished during solidification, and the shell of the casting becomes weaker, thus increasing shrinkage cavities and shrinkage porosity. Propensity. Generally, factories control the phosphorus content to be less than 0.08%.

(3) Rare earth and magnesium: Too high a residual amount of rare earth will deteriorate the shape of graphite and reduce the spheroidization rate, so the rare earth content should not be too high. Magnesium is an element that strongly stabilizes carbides and hinders graphitization. It can be seen that the amount of residual magnesium and residual rare earth will increase the whitening tendency of ductile iron and reduce the expansion of graphite. Therefore, when their content is high, they will also increase the tendency of shrinkage and porosity.

(4) Wall thickness: When a hard shell is formed on the surface of the casting, the higher the temperature of the molten metal inside, the greater the liquid shrinkage. The volume of shrinkage cavities and shrinkage porosity not only increases in absolute value, but also increases in relative value. In addition, if the wall thickness changes too suddenly, the isolated thick section cannot be fed, which increases the tendency of shrinkage and porosity.

(5) Temperature: High pouring temperature is conducive to feeding, but too high will increase the amount of liquid shrinkage, which is detrimental to eliminating shrinkage cavities and shrinkage porosity. Therefore, the pouring temperature should be reasonably selected according to the specific situation, generally 1300 to 1350°C is appropriate.

(6) The tightness of the sand mold: If the tightness of the sand mold is too low or uneven, the mold cavity will expand under the action of metal static pressure or expansion force after pouring, causing the original metal to be insufficiently fed. Causes shrinkage cavities and porosity in castings.

(7) Pouring risers and chilled iron: If the pouring system, risers and chilled iron are not properly set up, the sequential solidification of the molten metal cannot be guaranteed; in addition, the number, size and connection of the risers to the castings will affect the filling of the risers. shrinkage effect.

Therefore, the appearance inspection of finished ductile iron castings is an important task in ductile iron castings. The surface quality of the product is required to meet relevant industry standards.

.jpg) Precautions for the production of ductile iron castings

Precautions for the production of ductile iron castings

Ductile iron pieces using national standard iron

Ductile iron pieces using national standard iron

Fluidity and casting process of nodular cast iron

Fluidity and casting process of nodular cast iron

.jpg) Ductile Iron Casting QT600-3(8)

Ductile Iron Casting QT600-3(8)

Nodular iron QT400-18 of Automobile oil pump

Nodular iron QT400-18 of Automobile oil pump

The emu pillow rail nodular cast iron

The emu pillow rail nodular cast iron

The application of ductile iron castings in automobile

The application of ductile iron castings in automobile