Five methods for distinguishing ductile iron Casting parts from gray cast iron parts

Five methods for distinguishing ductile iron Casting parts from gray cast iron parts

Factors affecting the performance of gray cast iron

Factors affecting the performance of gray cast iron

.jpg) Overview of the three major uses of ductile iron parts

Overview of the three major uses of ductile iron parts

.jpg) How to identify the difference between ductile iron and gray cast iron

How to identify the difference between ductile iron and gray cast iron

What causes shrinkage and porosity in ductile iron castings

What causes shrinkage and porosity in ductile iron castings

What are the use occasions of high manganese steel and high chromium cast iron?

What are the use occasions of high manganese steel and high chromium cast iron?

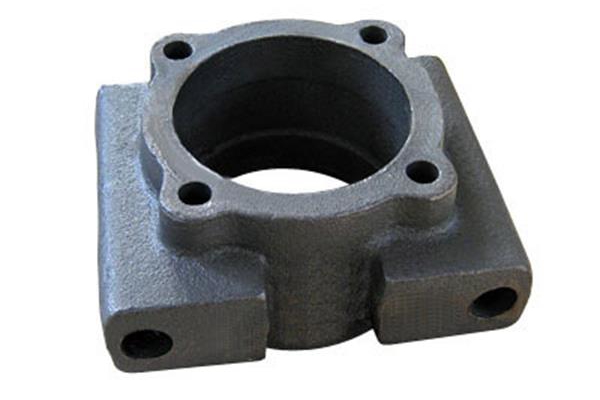

.jpg) Precautions for the production of ductile iron castings

Precautions for the production of ductile iron castings

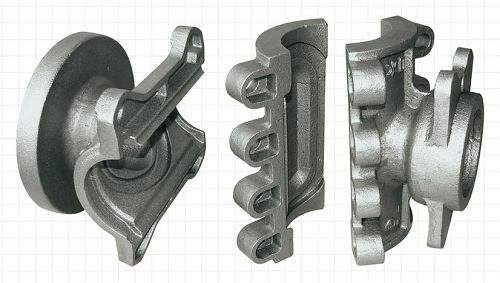

.jpg) Strength of ductile cast iron is greater than that of gray iron

Strength of ductile cast iron is greater than that of gray iron

.jpg) How to protect the ductile iron

How to protect the ductile iron

Ductile iron pieces using national standard iron

Ductile iron pieces using national standard iron